To know more about lithographic process and it’s basic types, click on the link below.

TAKE A LOOK : IC FABRICATION TECHNIQUES

TAKE A LOOK : PHOTOLITHOGRAPHY

The photolithography has its resolution limited by diffraction effects. To improve the resolution, therefore, the diffraction effects are reduced by reducing the wavelength. However, if the wavelength is reduced further, all optical materials become opaque because of the fundamental absorption, but transmission increases again in the X-ray region. This led to the requirement of X-rays for lithography purpose.

In X-ray lithography an X-ray source illuminates a mask, which casts shadows on to a resist-covered wafer. The mask and resist material for X-ray lithography are mainly determined by the absorption spectra of these materials in the X-ray region.

X-Ray Resist

An electron resist can also be referred to as an X-ray resist, since an X-ray resist is exposed largely by the photoelectrons produced during X-ray absorption. The energies of these photoelectrons are much smaller than the 10 keV to 50 keV energies used in electron lithography, making proximity effects negligible in the case of X-ray and promising higher ultimate resolution.

Most of the polymer resists containing only H, C, and 0, absorb very small X-ray flux. This small absorption has the advantage of providing uniform exposure throughout the resist thickness and the disadvantage of reduced sensitivity. .

As in optical and election lithography, the negative resists are limited in resolution by swelling during development. Thus minimum features of only 0.75 micro meters can be resolved in a commercial resist.

Proximity Printing

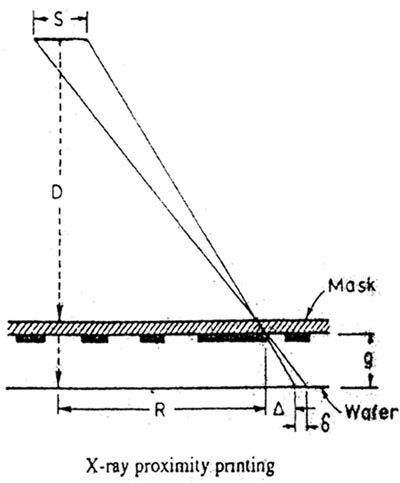

Since the wavelength of X-ray is small, diffraction effects can be ignored and simple geometrical considerations can be used in relating the image to the pattern on the mask. The opaque parts of the mask cast shadows on to the wafer below. The edge of the shadow is not absolutely sharp because of the finite diameter of the focal spot of the electrons on the anode [X-ray source] at a finite distance from the mask. The blurring of shadow can be evaded by the following equation.

∂ = Sg/D

Where ∂ = blur

g = gap between mask and the wafer

D = Distance of source from the mask

The various factors contributing to total registration error in X-ray lithography are machine imprecision and mask stacking errors due to placement errors of pattern generator] and mask distortion. Wafer process related contributions also have a role in the total registration error.

X-Ray Sources

In earlier years of development X-ray sources was often an electron beam evaporator with its chamber modified to accept a mask and wafer. The target metal could be changed easily to modify the X-ray spectrum. X-ray generation by electron bombardment is a very inefficient process. Most of the input power is converted into heat in the target. The X-ray flux is generally limited by the heat dissipation in the target. Much high X-ray fluxes are available from generators which have high speed targets. Another type of source, which provides still greater amount of flux, is the plasma discharge source in which the plasma is heated to a temperature high enough to produce X-radiation. The plasma chamber has problems such as reliability and contaminations.

X-Ray Masks

The mask for X-ray lithography consists of an absorber on a transmissive membrane substrate. The absorber is usually gold which is a heavy metal. Also it can be easily patterned. The transmissive membrane substrate is a polymer such as polymide and polyethylene terephthalate.

The photolithography has its resolution limited by diffraction effects. To improve the resolution, therefore, the diffraction effects are reduced by reducing the wavelength. However, if the wavelength is reduced further, all optical materials become opaque because of the fundamental absorption, but transmission increases again in the X-ray region. This led to the requirement of X-rays for lithography purpose.

In X-ray lithography an X-ray source illuminates a mask, which casts shadows on to a resist-covered wafer. The mask and resist material for X-ray lithography are mainly determined by the absorption spectra of these materials in the X-ray region.

X-Ray Resist

An electron resist can also be referred to as an X-ray resist, since an X-ray resist is exposed largely by the photoelectrons produced during X-ray absorption. The energies of these photoelectrons are much smaller than the 10 keV to 50 keV energies used in electron lithography, making proximity effects negligible in the case of X-ray and promising higher ultimate resolution.

Most of the polymer resists containing only H, C, and 0, absorb very small X-ray flux. This small absorption has the advantage of providing uniform exposure throughout the resist thickness and the disadvantage of reduced sensitivity. .

As in optical and election lithography, the negative resists are limited in resolution by swelling during development. Thus minimum features of only 0.75 micro meters can be resolved in a commercial resist.

Proximity Printing

Since the wavelength of X-ray is small, diffraction effects can be ignored and simple geometrical considerations can be used in relating the image to the pattern on the mask. The opaque parts of the mask cast shadows on to the wafer below. The edge of the shadow is not absolutely sharp because of the finite diameter of the focal spot of the electrons on the anode [X-ray source] at a finite distance from the mask. The blurring of shadow can be evaded by the following equation.

∂ = Sg/D

Where ∂ = blur

g = gap between mask and the wafer

D = Distance of source from the mask

The various factors contributing to total registration error in X-ray lithography are machine unprecision and mask stacking errors [due to placement errors of pattern generator] and mask distortion. Wafer process related contributions also have a role in the total registration error.

X-ray Sources

In earlier years of development X-ray sources was often an electron beam evaporator with its chamber modified to accept a mask and wafer. The target metal could be changed easily to modify the X-ray spectrum. X-ray generation by electron bombardment is a very inefficient process. Most of the input power is converted into heat in the target. The X-ray flux is generally limited by the heat dissipation in the target. Much high X-ray fluxes are available from generators which have high speed targets. Another type of source, which provides still greater amount of flux, is the plasma discharge source in which the plasma is heated to a temperature high enough to produce X-radiation. The plasma chamber has problems such as reliability and contaminations.

X-Kay Masks

The mask for X-ray lithography consists of an absorber on a transmissive membrane substrate. The absorber is usually gold which is a heavy metal. Also it can be easily patterned. The transmissive membrane substrate is a polymer such as polymide and polyethylene terephthalate.

7 Comments

“The various factors contributing to total registration error in X-ray lithography are machine unprecision”; actually in this case, the main problem is in the reporter’s failure to use the correctly spelled usage of the term, “unprecision”; the proper term is to use the correct word, “imprecision”. Please, in the interest of providing clarity in the presentation of the science behind the technology, have your writers employ spell-check, even if the editor misses such obvious mistakes.

Such elementary errors are at the very least, distracting the reader from gathering the information presented. Spell-check is even in the email program from which I am writing and was enough to catch the error when I tried to insert the above quote. My point? All you have to do is turn the bloody thing on!

James Lambert-Nash