In my earlier posts I have already explained the working of Charge-coupled devices and its application as an image sensor. Recently, most of the scanners and cameras have introduced a new image sensor called Contact Image Sensors [CIS].

Working of Contact Image Sensor

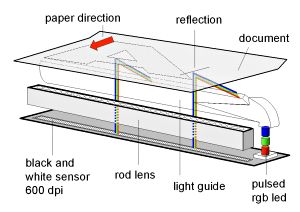

Contact Image Sensor is one compact module consisting of three sub-systems. They are

1. Illumination system

The illumination system consists of two sets of LED’s which is used to illuminate the document that is to be scanned. Each LED pack consists of LED’s of the three composite colours – Red, Green and Blue. These three colours join together to form the white light. The light from the LED is focussed with the help of light guides. The way the LED glow depends on the type of scan that is required. If a colour scan is needed all the LED’s will glow at high intensities. If a black and white scan is enough, the LED’s will shine simultaneously.

The main advantage of LED in CIS when compared to fluorescent bulbs in CCD is that they glow at a constant rate the minute they are turned on. But, fluorescent bulbs need a warm-up time as they begin to glow. They also have the advantage of being turned off whenever the device is not in use. Thus they help in saving a lot of power and are also environment friendly.

2. Optical system

The optical system consists of an array of lenses and a focus that is used to carry the light reflected from the document to be scanned to the light sensing system. Unlike a CCD, the optical system in CIS is shorter and less complex. This helps in saving more space and is also economical. As the apparatus is lighter and compact, it is applicable in making portable scanners.

3. Light sensing system

The light sensing system mainly consists of a sensor with a silicon surface. The light intensity that hits on the silicon surface varies according to the document to be scanned. The silicon surface will be divided into square cells. Though the same mechanism is carried out in a CCD, there is a difference in the ratio of the cell size to the information size. Here, the size of the information hitting on the silicon cell is same as the size of the cell. That is, for a 500 dpi scanner each cell will be 1/500″ across. Thus the ratio is 1:1. Thus, the need for the reduction or enlargement is no required in such a device. For this reason, the sensor will be kept very near to the document to be scanned. Most sensors rest right under the document at a distance of about 13 millimetres. As soon as the light hits the sensor, this will be recorded and will be converted into an electrical signal.

Take a look at the picture below to get a clear understanding.

Advantages of Contact Image Sensor (CCD vs CIS)

- The size of contact image sensors is very small and also lighter than the CCD sensors. They are always available as contact image sensor modules. That is, all its associated optical devices are included in a single compact module. This will also help in producing very flat and light-weight scanners. They also pave the way to applications in cameras and so on.

- These Contact image sensor scanners do not consume as much power as CCD scanners. They are also equipped to run with in battery power and can also be connected through USB port.

- When compared to a CCD, the sharpness of the image that is scanned is more for a contact image sensor. Thus they are applicable for scanning documents which requires even the smallest details to be displayed.

Disadvantages of Contact Image Sensor (CCD vs CIS)

- The image quality of a CIS is much lower when compared to a CCD sensor. The quality of the picture and the picture resolution is poor in comparison.

- As the depth of the field is limited to a certain extent, there will be problems while scanning a material that is nor completely flat in nature.

- In large scanning formats, CCD sensors use white LED’s or white fluorescent tubes for the colorization. In color compact image sensor, this is replaced by the composite color composite LED’s. The CIS LED’s cannot provide a wide range of color as CCD can. Thus CIS is not suitable for large scanning formats of photos or colourful documents with shadow details.

Applications of Contact Image Sensors

- The largest application of the device is in the field of scanning. Contact Image Sensor scanners have taken a large part of the industry. Since the CIS is lighter and smaller in size than CCD arrays, they are used in scanners that can be carried around. The most commonly used Contact Image Sensor scanner is the flat-bed scanner. The most famous brand among these is the Canon contact image sensor.

- Other applications of Contact image scanners include bar-code readers, electrograph and also optical identification technology.

PS: To know more about CCD and its applications here are some good resources;

TAKE A LOOK : CHARGE COUPLED DEVICES (CCD)

TAKE A LOOK : WORKING OF DIGITAL CAMERAS

TAKE A LOOK : WORKING OF SCANNER

4 Comments

can/have Contact Image Sensors be/been used in cameras? or in a scenario where a quick image needs to be taken at a close range?

@ Atula

No..Contact Image Sensors [CIS] are not used in cameras…This device produces lower image quality and poor depth of field, when compared to CCD devices. As a result they can create problems for taking pics of objects that are not flat. But, since it is small and lighter than a CCD device,and can fit in all the needed optical components in a compact module, it is very much suitable for devices like portable scanners, electrographs, bar code readers and optical identification technology.

please help me on microwave oven for a project

very usefull…. thank you so much