Studies have shown that the past decade had a rise in the number of cars to almost 500% than the previous one! This rise in cars has also been a major cause for the vast environmental pollution throughout the world. The introduction of electric cars has proved that they are very much environmental friendly and less pollute compared to gas cars. There has been a rapid increase in the sale of electric cars for the past few years.

Comparison between electric cars and gasoline cars

An electric car is powered by an electric motor. But, a gasoline car is powered by a petrol/diesel engine.

Since there are only electrical components, they are much easier to repair than other cars. They have only half the initial cost of a gasoline car. The power of electric cars is lesser than gasoline cars. But it is impossible to tell the difference between them while driving. While gasoline cars have a heavy noise, electric cars are smooth and silent while driving.

Hybrid cars have gained a lot of popularity nowadays. Among them, electric cars are the topmost in news. There has also been a trend of converting ordinary cars into electric cars. All you have to do is replace the engine with an electric motor and fit in an array of rechargeable batteries. You will also find that gasoline cars are very bulky in the interior with pipes, fuel lines and so on. But electric cars do not have any complexity. There are just a few wiring connections between each device.

How to make an electric car?

Modifying a gasoline car into an electric car

It is very simple to convert an ordinary car into an electric car. You must first know some basics about a gasoline car like the exact position of the engine, gas tank, muffler and so on. Here is a simple description of making an electric car.

For making an electric car the following components must be purchased.

- AC electric motors

- Electric controller

- Battery tray

- 12V Lead acid batteries

- Battery Charger

- Many motors for driving smaller parts

Given below is a well explained diagram of a car that shows both the physical components of an electrical as well as gasoline car. The comparison between them is also given.

Since the components for both the cars are different, they must be replaced. For this, all the major components like petrol/diesel engine, muffler, catalytic converter, petrol/diesel tank and also the exhaust pipe must be removed. The clutching mechanism must also be removed. There should not be any change in the manual transmission, except for its shifter. For further simplicity the shifter can be replaced with a switch, so that the forward and backward motion of the car can be controlled automatically. Connect the motor to the transmission. For controlled working of the AC motor, it must be connected to the controller. A number of lead acid batteries must be connected to the battery tray, which is correctly installed to the base of the car. For good driving response the battery must be able to produce at least 300V DC. For this, I would prefer two slots of the battery tray fitted with 25 batteries. For an ordinary car, the engine vacuum was used to give power to the bakes. In its absence a vacuum pump must be installed. Since the only driving source is from motors, the other mechanisms like power steering, water pump and also air conditioner should be connected to separate motors. Earlier they had driven power from the gasoline engine itself. As a part of maintenance, it is always better to include a recharger, so that the batteries can be automatically charged. For this, a 240V outlet is preffered.

Electric Car Statistics

Different parameters like mileage, speed, and life define the ability of a car. Here is an average reading of an electric car.

- The car has a maximum speed of 80km.

- The batteries have a life of almost three and a half to four years.

- All the batteries included weighs almost 500 kilograms.

- After a long drive, almost 12KW/h of electricity is needed to charge the car.

When comparing these parameters to an ordinary petrol/diesel car, you will get a huge difference in the pricing. There is almost 30% difference in the expense for each kilometre. But, the initial cost for an electric car will be very high. The batteries itself will cost up to $2000. They will last for a minimum of 25,000 miles.

Working of an Electric Car

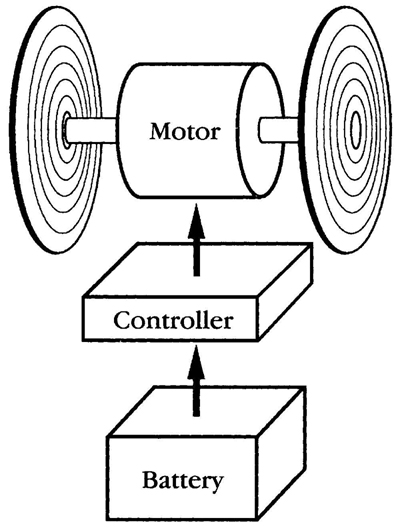

An electric car simply consists of three main components – Battery, controller and electric motor.

The base of any car is the battery. As told earlier, the battery used for this car is very expensive. By using lead acid batteries, the weight of the car increases a lot (>>1000 pounds). As the number of batteries range from 50 to more, they occupy a lot of space as well. They generate lesser driving powers comparing to gasoline cars. After a long drive, they need at least ten hours to get recharged completely. Apart from the battery used for the car mechanism, there is also an additional 12 V battery on board. This is needed to provide power for other components like wipers, radio, and air conditioner and so on. But the extra expense comes when you have to recharge the battery. You will need a 300V Dc to 12V DC converter.

As told earlier we need 300V DC to drive the AC motor. This rating is converted to 240V AC and is sent to the motor with the help of the converter. This can only be done using a set of transistors, which will convert the DC signal into sine waves rapidly. Thus when the accelerator is fully pressed, the controller produces almost 96 V to the motor. If the accelerator is released, the controller delivers 0V. Thus the controller stands as a buyer of power from the battery and giver of power to the motor. As the accelerator is pressed in different modes, the controller is supposed to give an output power accordingly. So, variable potentiometers are connected between the accelerator and the controller, so that variable, but proportional power can be delivered to the motor. But, if the potentiometer goes wrong the result can be fatal. So, as a safety measure, there are two potentiometers connected to the accelerator. If both show equal value, then the controller proceeds. If they are different, the controller stops working. The greatest disadvantage of this is that the whole car stops working if a single potentiometer goes wrong. In most of the cars, the controller is just a normal switch with an ON position while accelerating and an OFF position while decelerating. But, this is difficult for the driver as he will not get a flow. Thus the controller acts as a pulsator. It notices the value of potentiometer and rapidly switches the proportional power to the motor.

The motors used in electric cars can be AC or DC. Mostly DC motors are preferred than AC motors because they are simple to configure and are not at all expensive. For AC motors 3-phase motors have to be used, running at 240V AC. DC motors, on the other hand requires only (96-192)Volts. DC motors can also be overdriven for a short period of time.

29 Comments

Okay guys these plans are great. But, has nobody thought to use voltage doublers to speed up the charge time while using solar panels to power the car through the day.

I mean seriously. If you took a car the size of a prius and added some room and then put solar panels on the top of the car while simoltaneously using a voltage doubler extended to D and C-10 you would greatly reduce the time to charge the acid-lead batteries.

I am making a simple electric car using a BRUSHLESS DC MOTOR.But the problem is that whenever i switch on the key the car starts moving. plz tellHow to prevent this sudden motion of the car….

Did you try starting the car with the brake on.

try to use a potentiometer or variable resistance as ur accelerator when u accelerate the voltage will increase gradually and motor would start smoothly

why you did not install alltanator to recharge a car battery during motion of the motors?

Full machnism of electric motor that drive a car and battery mechanism..

Can please give the actual circuit diagram or complete detailed mechanism of electric car???

can u give the complete circuit diagram for the project.

what about coding portion ??

i want clear mechanism of electric car how it works and its connections, what kind of batteries can be taken and how they should be join to produce more power for vehicle.

i want clear mechanism of electric car how it works and its connections, what kind of batteries can be taken and how they should be join to produce more power for vehicle. please reply me as soon as possible.

i want clear mechanism of electric car how it works and its connections, what kind of batteries can be taken and how they should be join to produce more power for vehicle.

ok, at present dc motor only used. And also poladian technology they use to get good power in low volt

an u please mail me the exact working way of electric car . i have an idea and thinking of doing a project on it .. my project is based on usage of car for long time with minimum power . if u please mail me how the exact connections r made and what kind of materials r used in each set of places than it would be helpful for me . i even want to know how much amount of dynamo power is required to generate one revolution of a wheel . and the use of small solar panels will it not be useful in charging the battery we use in electric cars . please i expect a quick reply from your side

i am very suprise when i heard about the electric car,becouse this was my dreams always thinking of how to construct this amazing car,but i finaly loose hope becouse my country can not produce even a car battery.So i will be very happy if you can employ me and try my own special talent.am sure you will be very proud of getting me.

agree with eric, ‘..few batteries can be used in conjunction with an alternator circuit to recharge the batteries whiles the car is moving..’ than 8 hour recharges!

i have a one question , how to find quality battery and compact battery ,long life ,easy to charge and motor also….

can u please mail me the exact working way of electric car . i have an idea and thinking of doing a project on it .. my project is based on usage of car for long time with minimum power . if u please mail me how the exact connections r made and what kind of materials r used in each set of places than it would be helpful for me . i even want to know how much amount of dynamo power is required to generate one revolution of a wheel . and the use of small solar panels will it not be useful in charging the battery we use in electric cars . please i expect a quick reply from your side

After reading this content i found right direction for my future project.

@rezwan

in addition to johns info, nowadays a research on using algaes as the source of charges n also as the battries r in prgress, these can hold large amount of charges n can charge very fastly too,..

I think I have just read something about my dream of making an electric/electronic car.But I think it will be somehow difficult to get such a number of batteries for this project and I think just few batteries can be used in conjunction with an alternator circuit to recharge the batteries whiles the car is moving.

Electric cars is a hot topic around the world these days, and to obtain more info, a good place to start is

http://en.wikipedia.org/wiki/Electric_car….

Rolfi

Nice article. Do you know if anyone is currently working on a more efficient batteries? Something that can hold the charges longer and don’t take that much time to recharge.

@ Rezwan

There are batteries which can hold the charges for a long time – Ni-Mh batteries. They are very efficient and also last for almost 10 years. The only problem is the cost. They cost almost $30,000 for a car pack. That is almost 15 times more than an acid-lead battery!!