LM1830 based liquid level indicator circuit.

LM1830 is a monolithic integrated circuit that can be used in liquid level indicator / control systems. Manufactured by National Semiconductors, the LM1830 can detect the presence or absence of polar fluids . Circuits based on this IC requires minimum number of external components and AC signal is passed through the sensing probe immersed in the fluid. Usage of AC signal for detection prevents electrolysis and this makes the probes long lasting. The IC is capable of driving a LED, high impedance tweeter or a low power relay at its output.

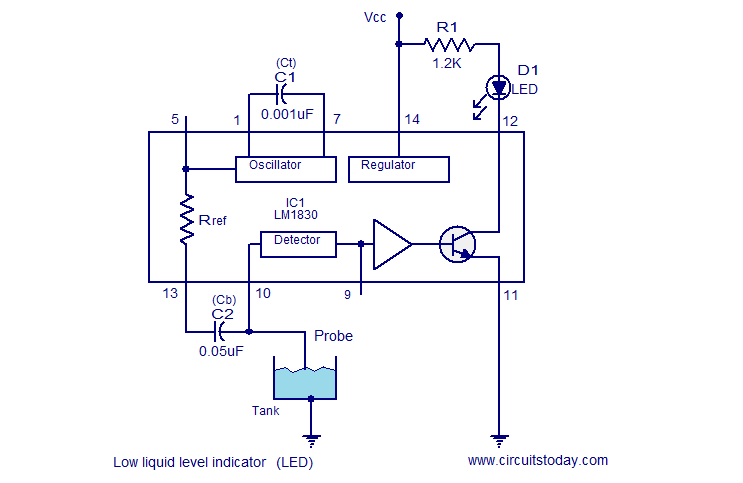

The circuit of a low liquid level indicator with LED is shown above. Capacitor Ct sets the frequency of the internal oscillator. With the give value of C1 the frequency will be around 6KHz. Capacitor Cb couples the oscillator output to the probe and it ensures that no DC signal is applied to the probe. The circuit detects the fluid level by comparing the probe to ground resistance with the internal reference resistor Rref.

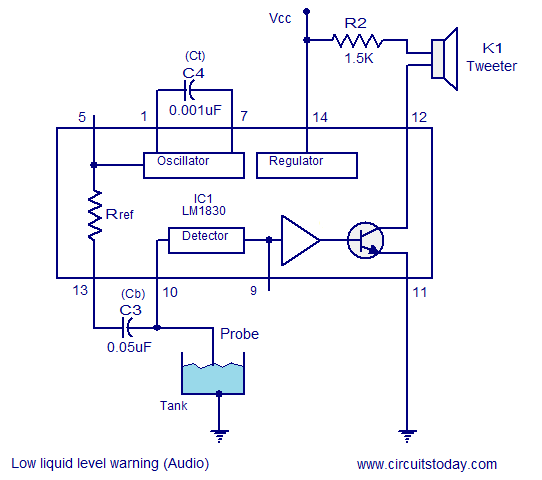

When the probe to ground resistance goes above the Rref the oscillator output is coupled to the base of the internal output transistor making it conducting. The LED connected to the collector (between pin 12 and Vcc) is driven. Since the base of the transistor is driven using the oscillator, actually the transistor is being switched at the oscillator’s output frequency @50% duty cycle. There is no problem in driving the LED using AC signal and this method is very useful when it comes to use a loud speaker as the indicator. Loud speakers can be driven only by using AC signals and a DC signal will not produce any sound out of the speaker. The circuit diagram of a liquid level indicator using loud speaker at its output is shown below. The circuit is similar to the first circuit except that the LED is replaced by a loud speaker and the load current limiting resistor is changed from 1.2K to 1.5K.

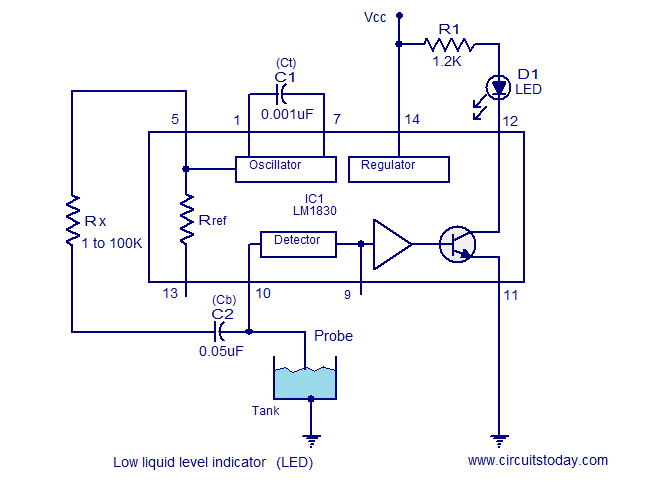

Low liquid level indicator with external reference resistor.

Some time there may be situations when the fluid resistance (probe to ground) do not match with the 13K internal reference resistor. In such cases there is option to avoid the internal reference resistor and an external reference resistor of your choice (Rx in the circuit) can be employed. The oscillators output is directly available at pin 5 and the Rx connects the oscillator output to the probe through the blocking capacitor. The circuit diagram for the above said scheme is shown below.

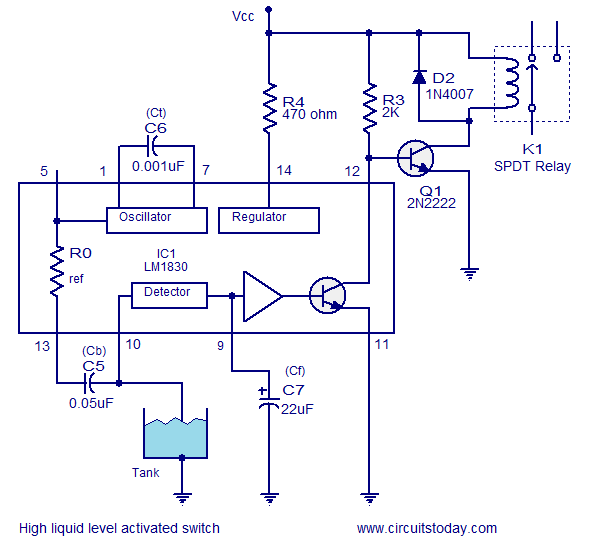

High liquid level activated switch.

A method for activating a relay when the liquid level exceeds a predetermined level is shown here. DC voltage is required for driving the relay and AC voltage cannot be used here just like what we did in the case of LED and speaker. Pin 9 of the IC can be used to solve this problem. A capacitor connected from this pin to ground will keep the internal output transistor steadily ON whenever the probe resistance goes higher than the reference resistor. External transistor Q1 is connected to the collector of the internal transistor. The load that is the relay is connected at the collector of Q1. When the probe is not touching the water it equal to an open circuit situation and surely the probe resistance will be many M ohms and it is greater than the Rref(13K). The internal transistor will be switched ON and Q1 whose base is connected to the collector of the internal transistor will be in OFF condition keeping the relay inactive. When the reverse scenario occurs (fluid level touches the probe) the internal transistor is switched OFF and this in turn makes the transistor Q1 ON resulting in the activation. The load connected through the relay whether pump, lamp, alarm, solenoid valve or anything is driven. Resistor R3 limits the collector current of the internal transistor while resistor R4 provides protection to the IC from transients.

Probe: The probe used here can be any metal rod with size and shape of your choice. The tank must be made of metal and it should be properly grounded. For non metal tanks fix a small metal contactor at its bottom level and ground it. The probe must be placed at the level you want to monitor.

Notes.

- The circuit can be assembled on a Perf board.

- I used 12V DC for powering the circuit.

- Maximum supply voltage LM1830 can handle is 28V.

- The tweeter I used was of a 16 ohm type.

- The relay I used is a 200 ohm/12V type.

- Maximum load current Q1 (2N2222) can handle is 800mA.

- The switching current/voltage ratings of the relay must be according to the load you want to drive using it.

- It is recommended to mount the IC on a holder.

Note:- We have recently developed a Water Level Controller circuit using Microcotroller , which is fully functional. You may see the circuit if you are interested.

16 Comments

no

can i get LM1830 IC now?

Hai, Can it be used for Water level indicator in a Over head Tank

Hi Challa it is meant for normal water, hence can be used for our domestic use to control over head tank water level.

How could I use this circuit to control the Digital input on a microcontroller? I am looking to just ‘read’ the fact that the led is one or off on my micro-controller to monitor and report.

Thank you.

hi… all you’ve got to do is take a wire from the LED positive to the microcontroller pin, making sure that the microcontroller and the circuit have a common ground by connecting their grounds together.

Hi Rohit Pin No 5 is oscillator out put for external reference resistance. You have to connect the tweeter between Pin No12 and Vcc through suitable resistance. Please refer to the second circuit above.

Hello,

Pin 5 & ground are for the 16ohms tweeter, pls clarify,

Regards

yhj

Achei fantastico o site. gostaria de estar sendo atualizado constantemente caso seja possível.

Atenciosamente…

Washington Souza Gomes

Hi, can this sensor circuit be used to detect diesel fuel?

Regards

Geoff